Assembling miniatures and model kits is a skill many take for granted, myself included. It seems simple from the surface, just put pieces together and you’re done, right? Well, not exactly. One of the most important parts of constructing miniatures is choosing the right adhesive to hold everything together. Super glue or cyanoacrylate is especially popular among miniature hobbyists, model makers, wargamers, and the ever-passionate gunpla enthusiasts. We love super glue because of its quick-drying, strong and durable bond. However, not all super glues are created equal.

In this article, I take a closer look at its three main types—thin, medium, and thick viscosity super glues. Each type offers unique advantages for different aspects of assembly and type of modeling task. I’ll also go into a few limitations with tips and tricks to overcome them.

Key Takeaway (Tl;Dr)

- Cyanoacrylate in super glue forms quick bonds but allows little room for adjustments; viscosity is a crucial factor for selection.

- Low-viscosity glues like CYAPRO work well for small, detailed components but can be messy and less durable.

- High-viscosity glues such as GlueMasters are optimal for larger, heavy-duty pieces, and notorious for their usefulness in attaching magnets to tabletop wargaming miniatures; more control, slower cure time.

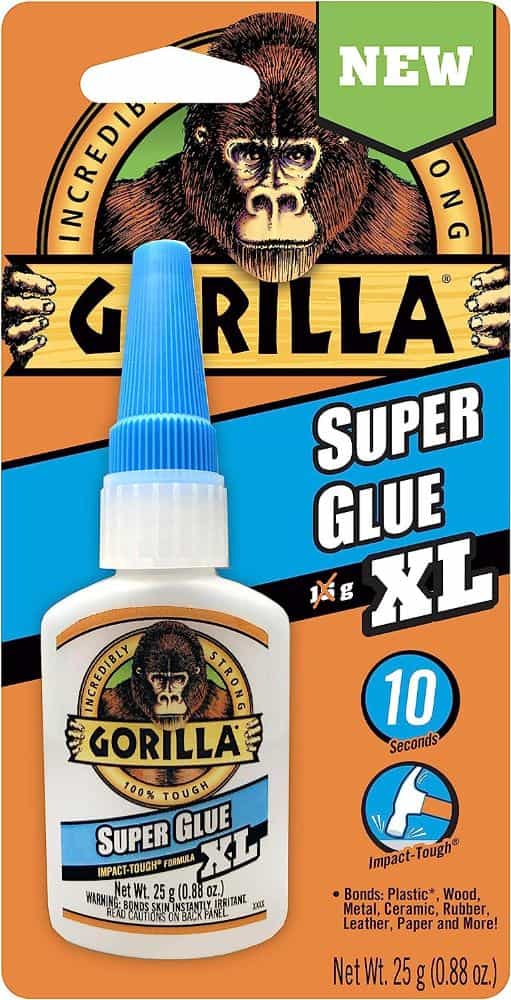

- Medium-viscosity options like Gorilla Super Glue offer a balanced but non-specialized approach to bonding speed and strength.

- Choice of super glue should be based on specific project needs, including control and time for adjustments.

In a Hurry? Here Are 3 Recommended Super glues

- Low Viscosity, Thin Cyanoacrylate Adhesive (Value, thin viscosity)

- Gorilla Super Glue (Medium viscosity, all-purpose and popular)

- Professional Grade Cyanoacrylate (CA) Super Glue (Thick viscosity, my favorite)

Read on to learn more about what I discovered about the different kinds of superglue and the best use for each type in miniature and model hobbies.

The Basics of Cyanoacrylate

What is cyanoacrylate glue?

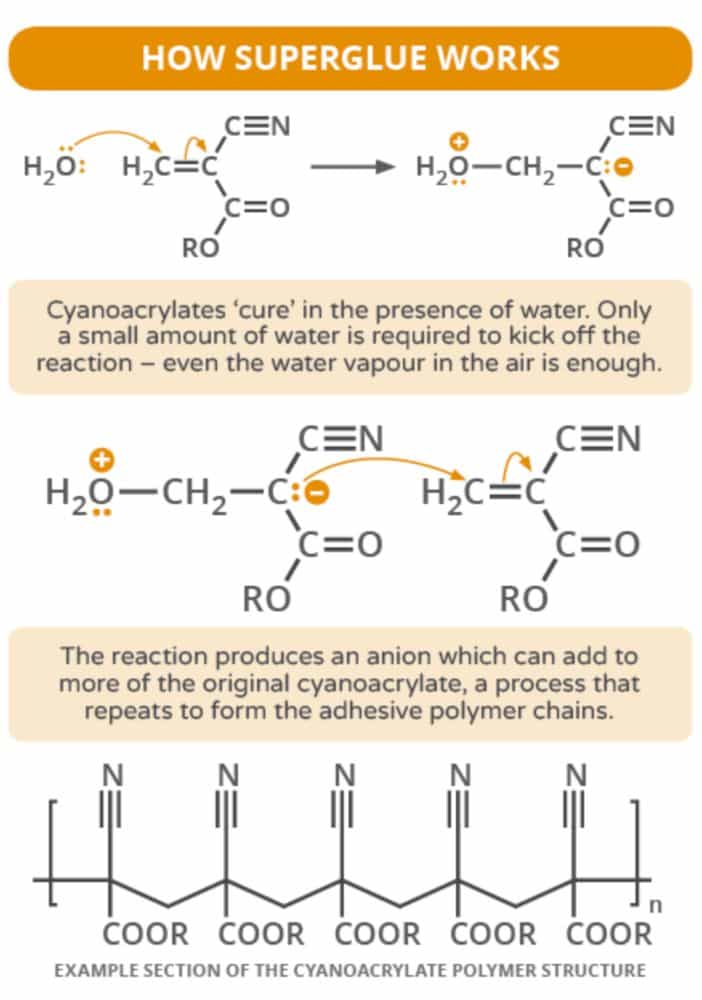

Cyanoacrylate (aka super glue) is a cyano-based group of polymers known for its strong adhesive properties. When applied to a surface, the liquid monomer reacts with water vapor in the air and begins polymerization, forming long chains of molecules that bond surfaces together. This makes super glue an excellent choice for bonding materials like plastic, metal, and even wood (source).

READ MORE: THE KRAZY HISTORY OF SUPERGLUE

Water: The Unsung Hero in Cyanoacrylate

Contrary to what you might think, water plays a vital role in the functioning of superglue. Yeah, you read that right. The water. The very thing we often strive to keep away from our model sets. But without it, our favorite cyanoacrylate wouldn’t be quite so… super.

Here’s how it works: Cyanoacrylate is an acrylic resin that rapidly polymerizes in the presence of water (source). This means that when you apply super glue to a surface, it’s not the air that triggers the bonding process. It’s the water vapor present in the air. This water vapor initiates a reaction that forms tight molecular chains, bonding the surfaces together almost instantly.

This is the reason why superglue bonds so well to your skin. Our skin’s surface is never completely dry, making it an easy target for superglue. A pro tip I’ve used on numerous occasions to remove pesky super glue from my fingers is to wipe my hands with nail polish remover which contains acetone.

The acetone will break down the polymer chains, loosening the bond and allowing you to peel off any excess glue. But don’t worry, it’s safe for your skin in small amounts!

Another helpful tip: You’ll find acetone is helpful for other hobby tasks, such as cleaning off your tools and the residue build-up in your airbrush (use a tiny dab on a cotton tipped applicator to apply acetone/nail polish remover).

The Pros and Cons of Rapid Curing Superglue

How does rapid curing influence the effectiveness of super glue?

One of the standout features of super glue is its rapid curing time. This means it dries and sets extremely quickly, which can be a major plus when you’re working on a project and you just can’t wait for things to dry. For miniature builders, this is a godsend, allowing rapid progress in assembly and fewer delays in completing the project.

Pro tip: Do you have a clogged metal superglue nozzle? You can use the heat from a lighter to burn away dried glue inside a clogged metallic superglue dispensing tip.

However, like any other feature, rapid curing has its downsides too. Speedy drying times don’t always allow for adjustments or repositioning once the glue is applied. If you make a mistake or if the pieces are not aligned properly, fixing the issue can be a challenge. Furthermore, the glue can dry out and become unusable if not stored properly. It is also worth noting that while rapid curing is beneficial in a dry environment, high humidity can lead to premature curing before the glue is even out of the bottle.

Here’s a quick table to further illustrate the pros and cons of rapid curing in super glues:

| Pros | Cons |

|---|---|

| Rapid curing allows for quicker progress in assembly | Mistakes or misalignment are hard to fix due to fast drying |

| Fewer delays in completing the project | Can dry out in the nozzle and become unusable if not stored properly (e.g, replace the cap/cover quickly) |

| Beneficial and easier to use in dry environments | High humidity can lead to premature curing |

Super Glue viscosity: how does it matter?

Viscosity, measured in centipoise (cp), refers to a liquid’s resistance to flow or, in simpler terms, its ‘thickness’ (source). Think of water (low viscosity) versus honey (high viscosity). Now, when it comes to superglues, the viscosity level plays a significant role in determining its application and performance.

Thin super glues, typically under 5cp, flow readily, almost like water. They’re perfect for seeping into small cracks, bonding tightly-fitted parts, or wicking into porous materials. However, they set fast, sometimes in just a few seconds, which doesn’t leave you much time for adjustments.

Medium viscosity super glues, ranging from 100-150cp, give you a bit more control during application and slightly longer set times. They fill small gaps efficiently and are suitable for parts that need a bit of positioning before the bond sets.

Thick super glues, usually over 1500cp, are gel-like and allow ample time for adjustments before they set. They excel in filling larger gaps and bonding irregular or uneven surfaces.

Thick or Thin Superglue for Miniature and Model Kit Assembly?

Let’s dive a bit deeper into the question that puzzles many miniature builders: Should you use thick or thin super glue for your model kits?

RELATED: BEST GLUE FOR MINIATURES AND MODELS

The answer is not straightforward, as it depends on factors like the material, size, and complexity of the parts you’re working with. Here’s an overview:

Thin Viscosity Super Glue: The Go-To for Minute Details

Traits and Applications:

- Low Viscosity: Generally measures around 5-10 cP.

- Fast Polymerization: Remarkably quick curing time, facilitated by its low viscosity.

- Capillary Action: Excellent for bonding tightly fitting miniature parts, such as limbs and weaponry.

- Surface Finishing: Particularly popular for simulating water effects in dioramas.

Examples in Practice:

- Model Kit: Gundam Real Grade (RG) Kits

- Application: A prime choice for securing tiny parts like manipulators or intricate internal mechanisms.

- Tabletop Miniatures: Warhammer 40k Eldar Aspect Warriors

- Application: Highly effective for attaching small, elaborate pieces like antennas and weapon tips.

- Scale Model: Airfix 1/72 Aircraft Models

- Application: A preferred option for bonding small cockpit details and slim fuselage sections.

Thin Super Glue

Pros

- Quick drying: Cures within 5-10 seconds, allowing you to work quickly in your project

- Precision: Great for high precision part assembly, small detailed pieces, e.g., Gunpla kits, where thicker glues would be harder to control

- Smooth application: Low viscosity helps spread over slim, narrow surfaces

Cons

- Messy: Runny super glue risks over application with seepage into unintended areas

- Weaker bonds: Fragile bonding due to chemical nature of thin viscosity super glues

- Poor gap filling: Not the best choice for filling gaps or bridging seams

Recommended Brand (Thin Superglue)

Low Viscosity, Thin Cyanoacrylate Adhesive

After experimenting with various options, CYAPRO Professional Grade Cyanoacrylate Super Glue has become my preferred choice for several reasons. It sets in less than 5 seconds due to its low viscosity, allowing for a strong bond. The package includes three micro-tips for precise application, along with an additional clog-preventing applicator. Moreover, it’s compatible with a wide range of materials, from plastic, pewter metal, and resin. For basing miniatures, I’ve also used this to attach small bits of flock, too.

RELATED: BEST GAP FILLERS FOR ASSEMBLING MODELS AND MINIATURES

Thick Viscosity Super Glue: For the Heavy Lifting

Traits and Applications:

- High Viscosity: Generally in the ballpark of 1000-1500 cP.

- Slower Polymerization: Extended curing time due to its thicker constitution.

- Structural Integrity: Ideal for heavy parts that require a sturdy bond.

- Gap Filling: A reliable choice when additional fillers are not desirable

- Stronger bonds: A powerful bond across a variety of applications, including adding magnets to wargaming miniatures, such as Warhammer 40k bits

Examples in Practice:

- Model Kit: Tamiya 1/16 Tank Kits

- Application: Suited for large, heavy parts like turrets and tank tracks.

- Tabletop Miniatures: Dungeons & Dragons Icons of the Realms

- Application: Effective for attaching expansive components such as dragon wings.

- Scale Model: Revell 1/25 Car Models

- Application: Optimal for bonding chassis to body and securing large interior components.

Thick Super Glue

Pros

- Gap filling: Capable of bonding large parts that have gaps

- Magnetizing models: Great for bonding rare Earth magnets to plastic model kits, e.g., Warhammer miniatures

- Strong bonds: When applied correctly, the bonds created with thick super glue are incredibly strong

- Control: Gel-like character with high viscosity makes this easy to apply across a wide range of surface types and materials

Cons

- Dries slower: Thicker super glue takes a bit longer to dry (up to a minute)

- Inadequate for small parts: Thicker consistency means thicker super glue can be cumbersome to apply on tiny parts

Recommended Brand (Thick Superglue)

Professional Grade Cyanoacrylate (CA) Super Glue

This is my favorite superglue for most miniature assembly projects. It’s a workhorse superglue. Glue Masters Industrial-Strength Cyanoacrylat (thick viscosity) sets in a matter of seconds—specifically under a minute—though it’s not the quickest on the market. With a viscosity rated at 1500 CPS, this glue gives you a good deal of control, which is especially beneficial when dealing with intricate models like space marine arms, weapon bits, scale model terrain, buildings, and more.

In a pinch, I’ve also used this in household tasks beyond hobbyist activities. It bonds really well across a variety of materials including wood, rubber, and the ABS plastic you find in kids’ toys. It’s also one of the best value superglues I’ve found on Amazon. In a per ounce (or gram) cost-analysis, you won’t find a more affordable super glue that is this reliable.

Medium Viscosity Super Glue: The Balanced Choice

Traits and Applications:

- Moderate Viscosity: Usually falls within the 100-200 cP range.

- Balanced Polymerization: A middle-of-the-road curing time lends it flexibility.

- General Assembly: Suitable for a variety of model components, from minute to sizable.

- Detail Work: Adept at handling parts that might not fit perfectly together.

Examples in Practice:

- Model Kit: Bandai Star Wars Model Kits

- Application: Apt for general assembly, including limbs and armor pieces.

- Tabletop Miniatures: Warhammer 40k Space Marine Tactical Squad

- Application: A jack-of-all-trades, suitable for small and large parts alike.

- Scale Model: Trumpeter 1/350 Ship Models

- Application: Versatile enough for deck details and superstructure components.

Medium Super Glue

Pros

- Versatility: All-purpose superglue that can handle small and medium-sized part assembly

- Drying time: Cures quickly under 60 seconds

- Gap filling: Limited ability to fill and bridge gaps between parts

Cons

- Jack-of-all-trades: Versatile, but not outstanding in any single task

Recommended Brand (Medium Viscosity Superglue)

It’s not as thick or thin as the other two superglues that I’ve noted above. But, Gorilla Super Glue is one of the most popular cyanoacrylate adhesives you’ll find in the miniature and modeling hobby space. This is for good reason: You can find this brand of super glue in almost any local hardware store. It’s also in many popular brick and mortar arts and crafts stores, too, e.g., Hobby Lobby, Michaels.

Gorilla glue is an all-purpose adhesive that I’ve used for years for various things. Though not my go-to super glue for miniature hobby things, due in part to it’s wide nozzle size which is cumbersome for applying on small surfaces, I prefer the thick viscosity glues for most projects (see Gluemasters and shown above). For non-hobby projects, Gorilla Super Glue does have versatility across many other needs you may have around the home or work. It sets quickly (under 45 seconds) and bonds to almost any material you can imagine.

Other Useful Information About Superglues

When you’re painting miniatures or building scale models, super glue isn’t just for sticking two pieces together. Here’s a quick overview on what else you should think about when using it.

Safety Precautions

Superglue releases fumes before and after the curing process has begun. The vapors are even more volatile when the ambient air temperature is warm (above 60℉ or 16℃). Both the stinging sensation in your nostrils or the tears from your eyes are signs you should probably find better ventilation when working with superglue. While I don’t use gloves, it is often a recommended idea to do so if you want to avoid accidently bonding your fingers together.

Surface Preparation: Stronger, More Reliable Bonds

The readiness of your workpieces directly influences the efficacy of the adhesive. A clean surface is imperative; remove all traces of dirt, oil, and other contaminants before application. For certain materials, a light sanding could improve the adhesive contact, offering increased grip.

Activators and Accelerators: Use Wisely

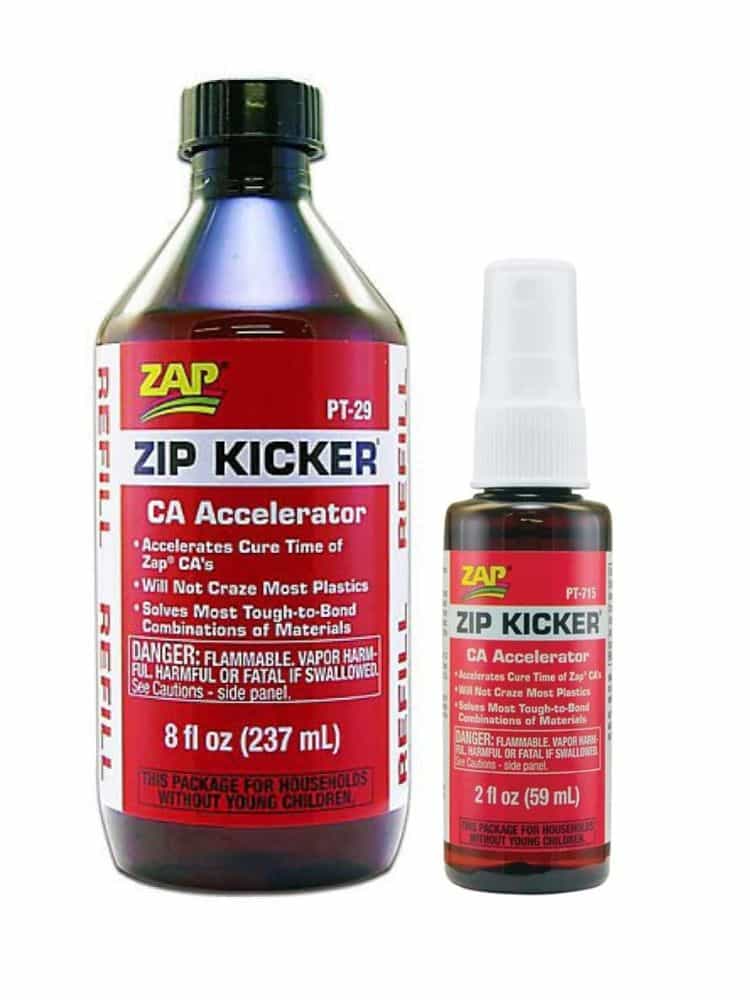

The use of activators or accelerators can be advantageous (source). These substances expedite the super glue’s curing process, enabling you to proceed to the next phase of your project more quickly.

When you’re a gaming convention, for example, you may need to perform rapid repairs on tabletop miniatures. Zip kicker or other catalyst can make the job go much quicker with less mess.

However, exercise caution; excessive use of catalysts can compromise the integrity of the bond, making your superglue bonds more susceptible to fractures.

Proper Storage: Safeguarding Usability and Saves You Money

Always cap/cover your superglue bottles when you’re not using them! Effective storage will prolong the lifespan of your super glue. If you’ve been in the hobby for a while, then you may have noticed that your super glues tend to lose their initial curing speed.

That bit of excess air exposure over time allows the super glue to lose some of its fast-curing properties. At this point, you may need to use that activator/catalyst to speed up the dry time again. To reduce this degradation of your superglues, store as instructed.

Fine Application Techniques

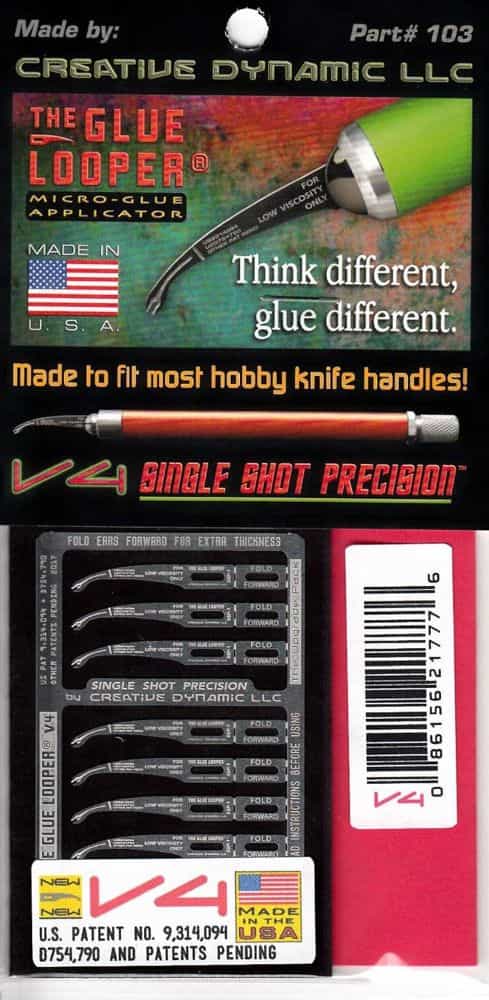

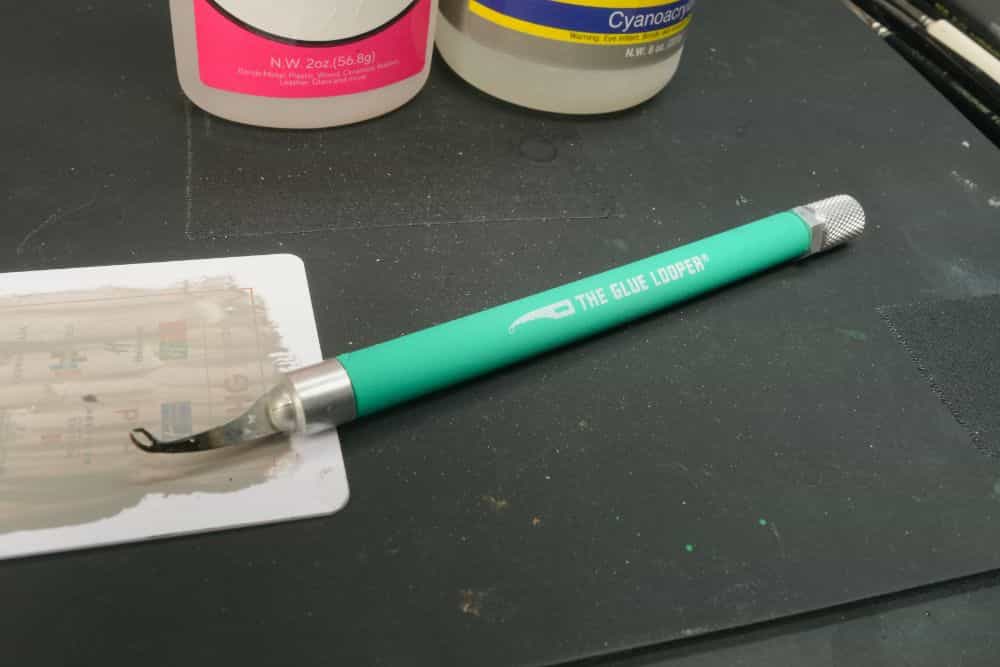

The art of applying super glue involves a delicate balance. I won’t go into much detail here about how I apply superglue to models. However, I will mention that I use a toothpick or a super glue looper applicator to precisely apply super glue on small, delicate surfaces.

The glue looper in particular is an amazing tool for careful glue application on super narrow, thin edges. Because super glue dries so quickly, every second counts especially with small bits you’re trying to glue together. You’ll have to move quick, so there is often some skill-up time required to be effective with assembling miniatures efficiently with superglues.

Note that “less is usually more” with superglues. Over-application can lead to an messy finish and extend curing times; whereas insufficient amounts risk a weaker bond.

Final Thoughts

In the art of assembling miniatures, the choice of super glue can significantly affect both the quality and durability of your work. The market offers cyanoacrylate adhesives in various viscosities: thin, medium, and thick. Each has its own set of advantages and drawbacks tailored for specific tasks. Thin super glues dry quickly and are excellent for precision but lack in strength and gap-filling capabilities. Thick glues offer robustness and better control but require a longer setting time. Medium-viscosity glues provide a balanced option suitable for a range of applications.

Safety measures and surface preparation are also crucial factors. Wearing protective gear and working in a well-ventilated area are essential for anyone engaged in this hobby.

When selecting a super glue for your miniature project, consider both your immediate requirements and the particularities of your work. Making an informed choice can make a marked difference in the end result.

I hope you enjoyed this article. I’m always looking to try out new things in the hobby.

Have you found the super glue that meets ALL your miniature hobby needs? Leave a comment below. I’d love to hear from you!

Tangible Day on YouTube (Miniatures and More!)